ISO 22000 Certification – Food Safety Management

Certification to ISO 22000 Certification – Food Safety Management, is a major milestone for aspiring companies within the food industry. In a previous post, we have already discussed the various management systems that exist within the ISO family.

In this post, we will go deeper into what ISO 22000 Certification – Food Safety Management really is.

ISO 22000 Certification – Food Safety Management vs HACCP

Therefore, the fundamental difference between HACCP and ISO 22000 is that:

- HACCP is a control plan

- ISO 22000 is a management system

Who needs HACCP?

The Hazard Analysis and Critical Control Point, also known as HACCP has been widely discussed and adopted in Malta. As per a document that was issued by the Department for Environmental Health in Malta, clear guidelines have been implemented on the power and duties of the Health Inspector(ate). In this document, a clear definition of who needs HACCP, Flexi HACCP, or a PRP is defined. The following entities are required to have a full HACCP plan:

- Manufacturers:

- Baby food – mil, non-milk excluding pasta

- Cook-chill – production for distribution only eg children/frozen ready to eat foods

- Non-alcoholic drinks

- Service:

- Hotels

- Caterer

- Hospitals

- Old People’s homes

- Meals-on-wheels

Prerequisites (PRPs)

Irrespective of whether the company is listed in the above types of businesses, there are certain prerequisites that must be applied in all food businesses as stipulated in EC Regulation 852/2004, namely:

- Cleaning / Sanitation

- Pest Control

- Waste management

- Personal Hygiene and training

- Plant & Equipment

- Zoning

- Premises and Structure

- Services (eg water, energy and drainage)

- Storage, distribution and transport

- Labelling and packaging (contact material)

- Additives

- Traceability

- Product Release and Recall

- Calibration

- Acceptance and Rejection of Goods

Requirements of HACCP

Unlike ISO 22000, HACCP is a Hazard Analysis and Critical Control Point – this means that individual risks are to be identified and treated whilst doing HACCP. The 7 HACCP Principles are:

- Conduct Hazard Analysis

- Determine Critical Control Points (CCP)

- Establish Critical Limits

- Establish system to monitor control of CCP

- Establish corrective action

- Establish verification procedures

- Establish Documentation & Recordkeeping

Requirements of ISO 22000 Certification – Food Safety Management

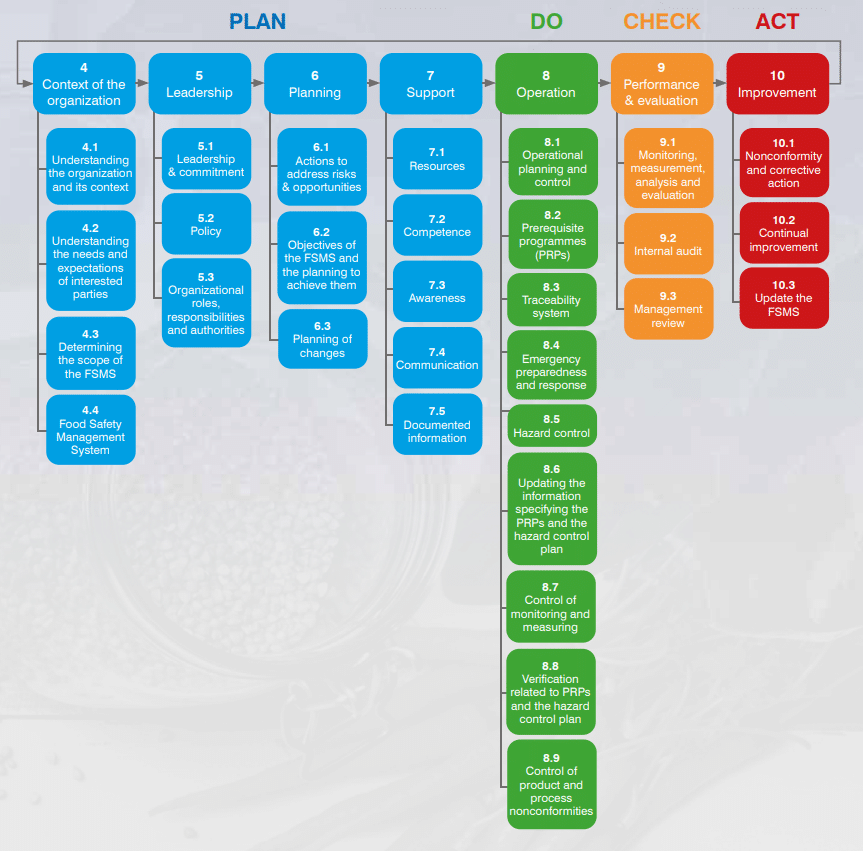

Just like other management systems, the ISO 22000 is split over 10 Clauses. As can be noted, the requirements of these 10 clauses are not very different from the requirements for ISO 9001 Certification.

Just like with other Management Systems within the ISO Family, most of the information is contained in Clause 8. In fact, for ISO 22000, the only 2 elements for a safe management system to handle food are:

- Assemble HACCP Team – Clause 5.3

- Establish documentation and record keeping – Clause 7.2

Requirements of Clause 8 within ISO 22000

So, what does the ISO 22000 ask us to do (over what is required for ISO 900) to ensure that we are consistently delivering a high-quality product to our food-business customers?

- 8.1 – Operational Planning and Control – plan, implement, control, maintain and updated processes to deliver the product to the customer

- 8.2 – Prerequisite programs – PRPs are a key aspect of any food safety system, and have been define above

- 8.3 – Traceability system – including the reconciliation of quantities (end products vs ingredients)

- 8.4 – Emergency Preparedness and Response – a risk assessment on what can go wrong, and the implementation of specific measures

- 8.5 – Hazard Control – practically relates to doing a HACCP, and the idea is to identify, prioritize and mitigate certain hazards

ISO 22000 vs ISO 9001 – Similarities & Differences

ISO 22000 relates to food safety management systems and is specifically designed for any company within the food chain. ISO 9001, on the other hand, is a generic Quality Management System, that can cater to the needs of any company, within any industry.

Clauses 1-6

- Clause 4 – Conext of the organization (internal and external issues), including the definition of the interested parties – required for both ISO 9001 & ISO 22000

- Clause 5 – In ISO 9001, we have the quality Policy, while in the ISO 22000 we have the food safety management system – which is also a framework through which top management shall estbalish, implement and maintain a vision for continual imrpvement.

- Clause 6 – this Clause primarily talks about Risk Management & Food Management/Quality Objectives – within the context of their respective management sysem – the requirements for this Clause is the same for both standards

Clause 7

- This clause will be further split into the different sub-clauses

- 7.1.2 – people – Generally the requirement is the same, however for ISO 22000, there is an extra requirement which is that ” Where the assistance of external experts is used for the development, implementation, operation or assessment of the FSMS, evidence of agreement or contracts defining the competency, responsibility and authority of external experts shall be retained as documented information.” This requirement is tackled within 8.4.2 within ISO 9001.

- 7.4 – communication – is drastically different for the 2 certifications. ISO 22000 gives detailed information about the internal and external communication that must be carried out within the organization.

Clause 8

Clause 8 is the core Clause within the ISO Management Systems family. Clause 8 of ISO 9001 talks about the operational procedures within the company, namely:

- Sales

- Purchasing

- Operations

- Design & Development

On the other hand, ISO 22000 focuses on other elements within Clause 8, namely:

- Clause 8.2 – PRPs (Prerequisite programmes) – have been defined above, and this relates to setting up systems in palces to faciliate the preveention and/or reduction of contiminants in food products. This can also relate to Food Safety Hazards – commonly known as HACCP (Hazard Analysis Critical Control Point)

- Clause 8.3 – This clause in ISO 22000 talks about having a traceabilty system to idetnfiy incoming material, upto the stage where the product is sold to customers. A proper implementation of ISO 9001 will ensure that this requirement has been met (see 7.1.5.2 of ISO 9001).

- Clause 8.4 – Emergency perparendess and response – is a clause that encourages organizations to implement, and continually review a systems that deals with potential emergy situations that might have an impact on food safety. ISO 9001 briefly touches on this topic in Clauses 8.7 (control of non conforming output) & Clause 10.2 (Non-conformity & corrective action). And yet, Clause 8.4 in ISO 22000 asks us to consider how communication will flow, and that we periodically review the tests procedures.

- Clause 8.5 – Hazard Control – Given that the ISO 22000 standard is about food safety, it should not come in as a surprise that this is the most holistic Clause within the standard. The process appropach that is instilled within ISO 9001 comes into mind here. This Clause asks us to map out the proceses relating to the processes covered by the FSMS (Food Safety Management System). The mapping out of these processes ensures that we have a baseline on which to track the processes within our organization. Thereinafter, we will need to conduct a Hazard Control plan (HACCP/OPRP Plan) to control the effectiveness our processes.

- Clause 8.6 – is a simple Clause identifying the requirements for updating the information on the PRPs and HACCP

- Clause 8.7 – relates eto the control of monitoring and measuring resources, which is the same as Clause 7.1.5 in ISO 9001 – and states that any devices used to provide ‘readings’ must produce accurate values. And to enusre this, we must to calibration/vertification of this equipment.

- Clause 8.8 – This clause, once again, asks us to ensure that we have implemented the right techniques to verify the PRPs and the hazard control plan.

- Clause 8.9 – Control of product and process nonconformities, is clause 8.7 in ISO 9001 – and even though they are mostly similar, for ISO 22000 there is an extra requirement that the organization must identify the affected products accordingly. Furthermore, it goes on to states about how, for example potentiall unsafe products must be handled.

Clauses 9 & 10

Once again, Clauses 9 and 10 for ISO 9001 and for ISO 22000 are extremely similar in nature. These Clauses talk about monitoring of process and products – with the aim of continual improvement. These include processes for Internal Audit & Management Review.

Conclusion: ISO 22000 Certification – Food Safety Management

If you are operating in the food industry, ISO 22000 will most likely be required by your clients or suppliers now or in the coming future. Having said that, the benefits of ISO Certification when implemented by an experienced ISO Consultant greatly outweigh the cost for ISO certification.

If you’d like more information on how you can implement ISO 22000 within your business, feel free to get in touch on lukedesira@gmail.com or +356 79206686, and I, Luke Desira, would personally commit to helping your reach your business goals.

One Comment

Comments are closed.