Design & Development procedure as per ISO 9001

Here you will learn more about the Design & Development procedure as per ISO 9001. Design and development could be one of the key processes that need to be defined during an ISO 9001 certification process. If the company does not receive the requirements from the customer or interested parties, and therefore the company designs the products and services it offers, the design & development process must be created as per ISO 9001 clauses.

Design & Development Planning (8.3.2)

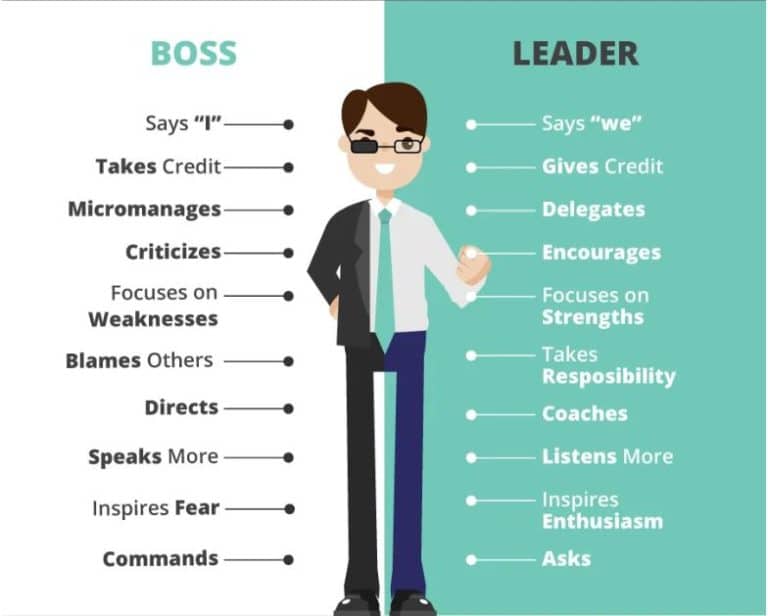

As a first step in any design process, the company must first and foremost confirm that it has the required resources to complete the job required. This refers to human skills, machinery and equipment, contacts and suppliers, or any other resource that would be required to deliver the product or service to the customer.

As a first step in the design process, the design team must go through the subsequent steps in the design process to determine the level of complexity of the project, to make sure that the company is up to the task. This has to be done before accepting the request from the customer to carry out the job.

Documented information must be kept to demonstrate that the planning of the design process has been completed.

ISO Frog | The Latest Project From Luke Desira

ISO Frog is the new solution for ISO Certification. This software is crafted by a team of ISO experts, led by the management systems specialist, Luke Desira.

Design and development processes can be complex, but ISO Frog is here to streamline them. The software includes templates and tools tailored for managing design and development activities in line with Clause 8.3 of ISO 9001:2015. From initial planning to final reviews, ISO Frog helps you maintain compliance while ensuring that all requirements are met. Ensure your products or services meet customer and regulatory requirements with ISO Frog.

Sign up today and be one of the first to gain early access to ISO Frog itself! You’ll be effectively helping us test ISO Frog. By signing up, you’ll be receiving:

Design & Development Inputs (8.3.3)

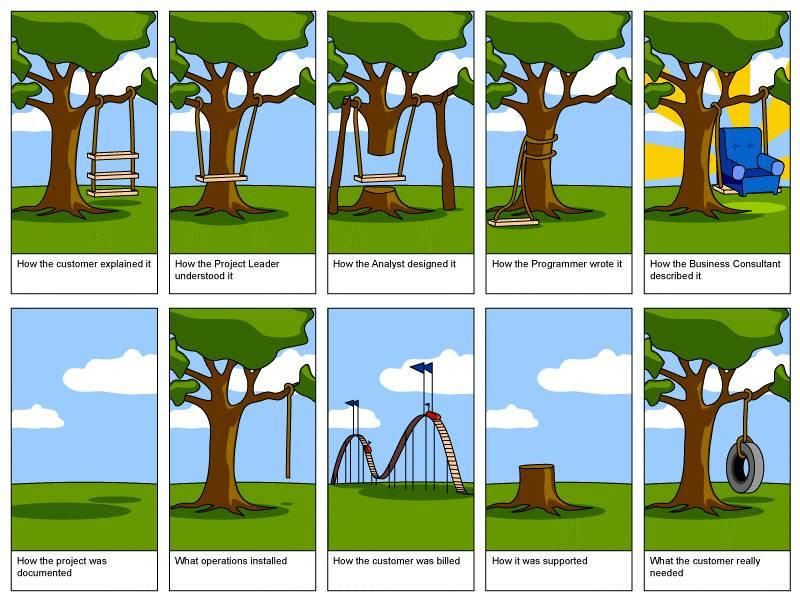

The role of any design project is to translate customer requirements into product or service specifications. That is to say, that we must convert descriptive customer requirements (for example a fast car) into product features (500 horsepower). After we have confirmed that the company has the required experience to carry out the job, we must extract the requirements from the customer.

There are many types of customer requirements, including:

- functional requirements – what the customer wants to achieve

- unstated requirements and standards of the industry – features of the product that the customer would take for granted

- statutory and regulatory requirements – any laws and regulations that dictate what features/elements a product must have

Given that the inputs are the foundation of the design process, these requirements must be clear and understandable by all involved. should there be any issues with the inputs, including conflicting ideas, they must be resolved prior to move on to the next step.

Design and development controls (8.3.4)

The design process usually takes weeks, if not months. The standard deliberately places the control of the design process between the input and the output stage to help us design a management system whereby reviews are done throughout the design process. A late decision in a design process might mean that the project would need to be retracted to previous stages, losing time and money, or worse, making irreparable mistakes.

At the control stage, we must have clear documented information to know that the design process is achieving the intended results. For example, through the definition of specific results to be achieved. Reviews and verification activities must also be done to ensure that the design outputs will meet the inputs. Should there be any necessary changes that are taken to change the course of a design to reach the intended purposes – such a change must be documented.

Design and development outputs (8.3.5)

Once the design and development activities have been completed, we will have the output. These outputs must meet the inputs requirements. Depending on the nature of the products/service being design, in this section, we must make reference to the monitoring and measuring equipment that is used to measure the outputs. For example, if we have designed a car that must reach a certain speed, we must define how to measure such speed – for example by using a calibrated stopwatch and measure the time the car takes to travel a known distance.

At this stage, we must also specify any constraints, or characteristics of the product or service, that are essential to ensure that safe and proper use of the product/service.

Changes in Design and Development Procedure (8.3.6)

A design process is very rarely a linear process. Within the Design & Development procedure as per ISO 9001, change requests might come from any of the interested parties, and depending on their relevance and importance – changes might be actioned. For the reason, ISO 9001 makes is a requirement for the company to retain documented information on:

- how changes will be recorded and communicated to the relevant interested parties

- results of reviews based on the changes

- who has the authority to accept or reject changes – given that such changes might have adverse effects on the product/service

- any additional actions that will be taken to prevent adverse impacts

Design & Development procedure as per ISO 9001

In conclusions, the Design & Development procedure as per ISO 9001 requires companies who want to be certified against the management system to clearly articulate the flow of information throughout the design process.

Driving improvement within the quality system doesn’t happen overnight, and there are multiple actions that must be taken to take the benefits of ISO Certification. A robust Design & Development procedure as per ISO 9001 is a strong first step towards a leaner company.

6 Comments

Comments are closed.